以下为报道截图:

以下为报道和译文:

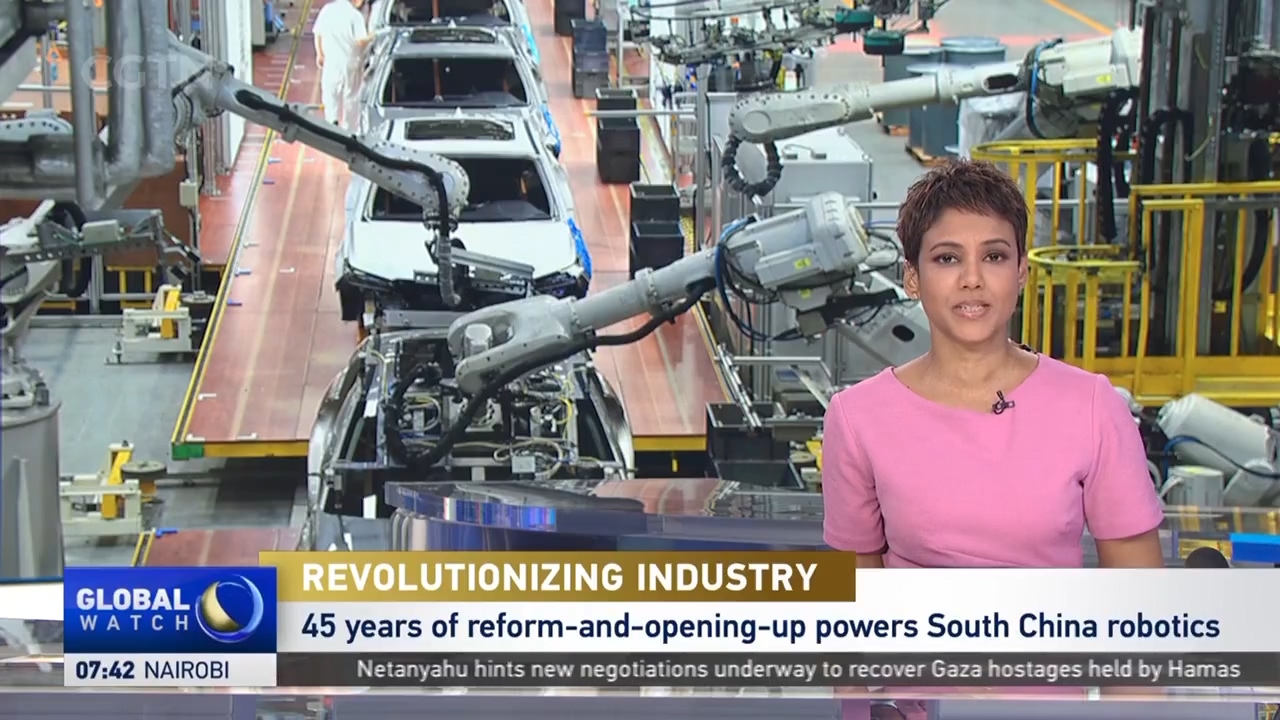

China uses more industrial robots than anywhere else in the world, a title it's held for nearly a decade. The sector is also undergoing rapid change, as domestic companies embrace new technologies. In Guangzhou, the biggest industrial robot maker in South China has evolved from importing foreign tech to pioneering world-leading solutions. And, it's now planning for the future. Huang Fei explains.

中国是世界上使用工业机器人最多的国家,这个头衔已经保持了近十年。随着国内企业接受新技术,该行业也在经历快速变化。在广州,华南地区最大的工业机器人制造商已经从引进外国技术发展到开拓世界领先的解决方案。而且,它现在正在为未来做计划。黄菲解释道。

Meet Sun Zhiqiang...

认识一下孙志强……

In 1995, this young auto engineer and salesman landed a ground-breaking contract, making his company the first manufacturing agent for Panasonic robots and welding machines in China.

1995年,一位年轻的汽车工程师兼推销员获得了一份开创性的合同,使他的公司成为松下机器人和焊接机在中国的第一家制造代理。

SUN ZHIQIANG Chairman and President, Guangzhou Risong Intelligent Technology "Back then, money was really tight. Manpower was cheap, but a robot cost hundreds of thousands of yuan. Support facilities and industrial gases weren't available either, so it was really difficult to promote such technology in China. I felt lost. But I knew China' open economy would create enough demand for high-end equipment, so I persisted."

广州江南电子平台(中国)有限公司股份有限公司董事长兼总裁孙志强:“那时候,资金真的很紧张。人力很便宜,但一个机器人要花几十万元。配套设施和工业气体也不具备,所以在中国推广这种技术真的很困难。我感到迷茫。但我知道中国开放的经济将为高端设备创造足够的需求,所以我坚持了下来。”

To foster high-end manufacturing, Guangzhou established a development zone, attracting venture capital and the presence of Fortune 500 companies.

为了培育高端制造业,广州建立了一个开发区,吸引了风险投资和财富500强企业的进驻。

Sun Zhiqiang's company played a pivotal role in the national drive for electric vehicles, becoming South China's leading supplier of production systems.

孙志强的公司在国家推动电动汽车发展的过程中发挥了关键作用,成为华南地区领先的生产系统供应商。

HUANG FEI Guangzhou "These are brand-new robotic arms packed up and ready to go. In the Chinese EV industry where competition is fierce, automakers are racing against the clock to innovate. And their production systems need to keep up with the latest designs. For industrial robot manufacturers, the challenge is creating production systems that are not just efficient but also flexible."

“这些是崭新的机械手臂,已经打包好,准备好了。在竞争激烈的中国电动汽车行业,汽车制造商们正在争分夺秒地进行创新。他们的生产系统需要跟上最新的设计。对于工业机器人制造商来说,挑战在于创造不仅高效而且灵活的生产系统。”

Sun's company boasts an agile production line capable of assembling a new car in less than one minute, and it accommodates eight different models simultaneously. They're able to meet the surging demand for robots in China.

孙志强的公司提供灵活的生产线,可以在不到一分钟的时间内组装一辆新车,同时容纳八种不同的车型。他们有能力满足中国对机器人不断增长的需求。

SUN ZHIQIANG Chairman and President, Guangzhou Risong Intelligent Technology "Intelligent manufacturing in China provides numerous case studies, allowing us to learn through trial and error. Now, we're contributing our solutions to the global industry. Technology has no borders, it involves a constant cycle of learning."

广州江南电子平台(中国)有限公司股份有限公司董事长兼总裁孙志强:“中国的智能制造提供了大量的案例研究,使我们能够在试验和错误中学习。现在,我们正在为全球行业贡献我们的解决方案。技术没有国界,它涉及到不断地学习循环。”

Industry insiders agree the next challenge is digitization, especially navigating Artificial Intelligence and the Internet of Things.

业内人士一致认为,下一个挑战是数字化,尤其是人工智能和物联网。

CHEN ZHUMING Professor, School of Business at Sun Yat-sen University "We are overtaking others, but not leading yet. We need to invest more in fundamental research. Local manufacturers can't achieve digitization on their own. They need algorithms, computing power and programming specialists. The question is, how can tech giants like Tencent, Alibaba and Huawei help to revolutionize manufacturing? There's a lot to be done here."

中山大学管理学院教授陈珠明:“我们正在超越别人,但还没有领先。我们需要加大对基础研究的投资。本土制造商无法凭借一己之力实现数字化。他们需要算法、计算能力和编程专家。问题是,腾讯、阿里巴巴和华为等科技巨头如何帮助制造业实现革命?这里有很多事情要做。”

45 years since Guangdong's factories welcomed international ventures, the southern trade capital continues to lead China's fourth industrial revolution. The challenge ahead is how far these robotic arms are able to connect to the "cloud," allowing them to truly embrace the technologies of tomorrow.

自45年前广东工厂向国际企业开放以来,这个南方贸易之都继续引领着中国的第四次工业革命。未来的挑战是,这些机械臂能够与“云”连接多远,从而真正拥抱未来的技术。

Huang Fei, CGTN, Guangzhou.

黄菲,CGTN广州报道。