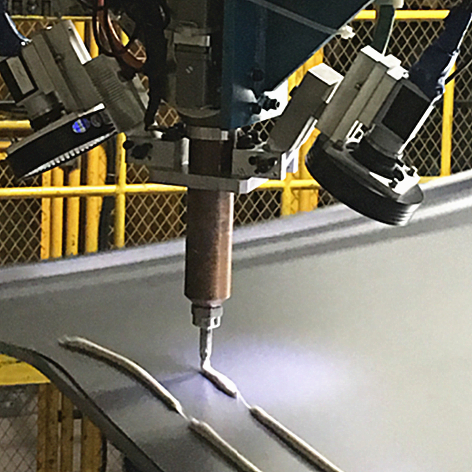

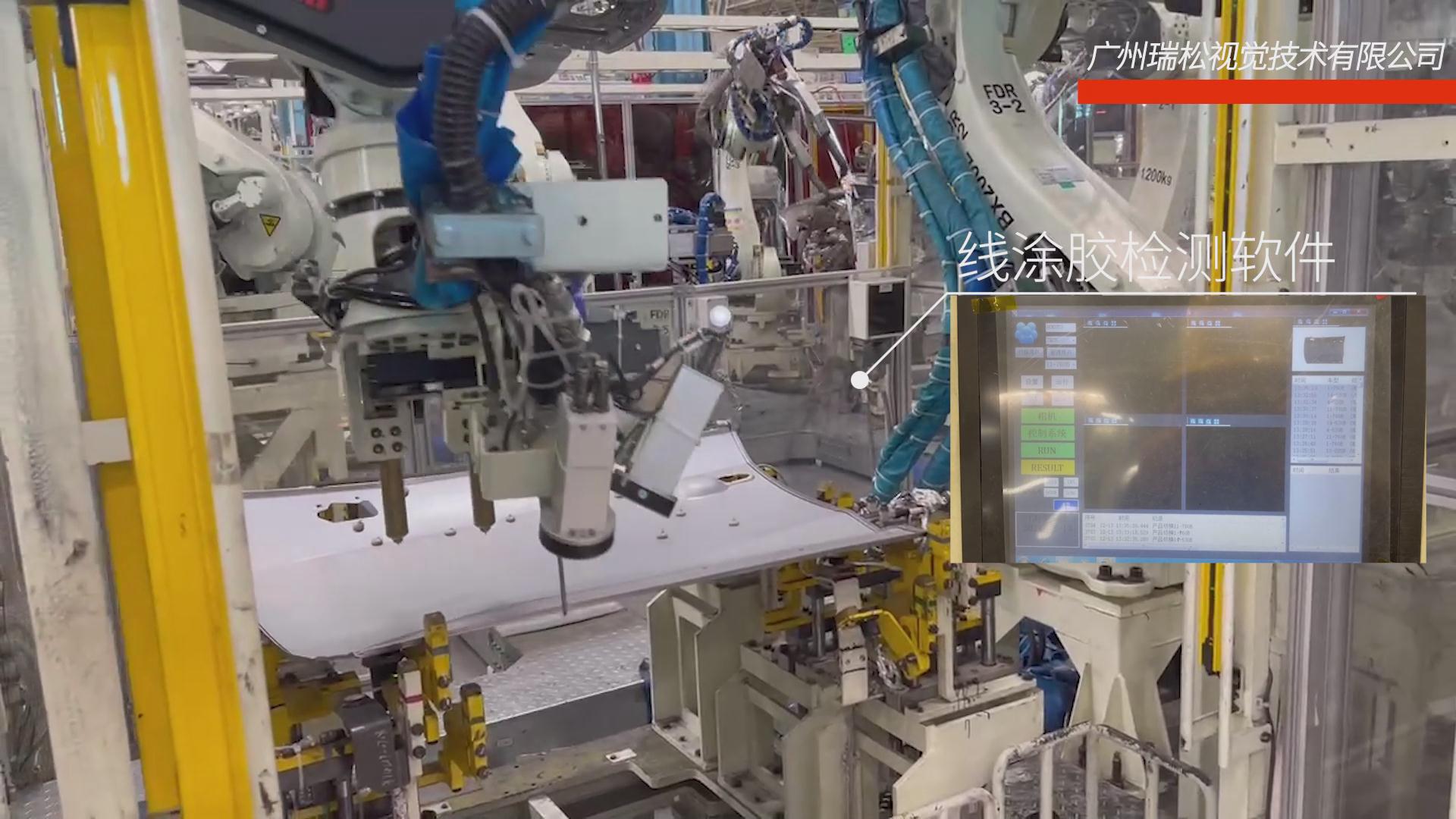

Principles of vision:

1. In the captured image, the gluing area is positioned.

2. The gluing inspection scope is determined according to the gluing positioning result, so as to speed up the processing speed and accuracy.

3. The characteristic data of the glue is extracted according to the boundary image of the glue.

4. The characteristic data of glue is processed and the glue width is measured.

5. The inspection result and OK/NG are determined according to the upper and lower limits already set.

Product applications: missed gluing, glue rolls, extremely thin glue, extremely large width of glue, excessive glue, glue deviation, and glue breakage