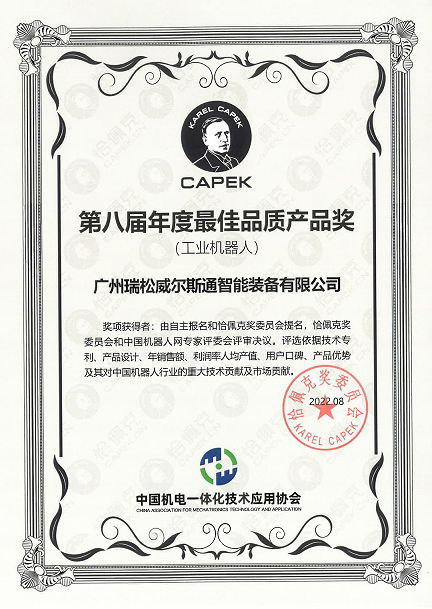

On August 27, 2022, the 12th China International Robot Summit Forum and the 8th Chapec Award Ceremony were successfully held in Wuhu, Anhui Province. The intelligent friction stir welding equipment of Guangzhou Risong Weldstone Intelligent Equipment Co., Ltd., a joint venture subsidiary of Risong Technology, won the 8th Chapec Annual Best Quality Product Award.

Risong won the 8th "Best Quality Product of the Year Award" in Chapec

This is the most direct and authoritative recognition for the high-quality, high-quality, and high-performance friction stir welding products independently developed by Risong. It also shows that Risong's friction stir welding technology is innovative and breakthrough, and the products can continuously meet customer needs and exceed customer expectations.

Risong Weldstone is committed to creating a world benchmark for intelligent manufacturing of lightweight materials, leading the development of the intelligent manufacturing industry of lightweight materials. By developing globally leading products and services such as robotic friction stir welding, gantry friction stir welding, C-type machine friction stir welding, and production line integration, we provide customers worldwide with intelligent digital welding, production line integration, and advanced manufacturing solutions in related fields.

1 C-type machine friction stir welding

In 2022, Risong Weldstone successfully released the independently developed 1206C friction stir welding equipment. The C-type machine has a high space utilization rate, and its bed is made of cast iron, with stable structure, good seismic performance, and stable welding performance. It is suitable for planar welding of aluminum alloy sheets such as electronic control/motor housings of new energy vehicles, radiators in the communication industry, and water cooled plates.

The highly integrated friction stir welding head of this product is designed using the equal strength structure theory to effectively solve the welding deformation problem of workpieces at different heights; Ensure the stability of welding accuracy; Equipped with normal following and small arc optimization functions to keep the mixing head consistent with the welding path and avoid welding defects; The standard constant pressure function effectively reduces welding defects caused by incoming material errors, clamping positioning errors, and inconsistencies with the ideal model.

2 Robot friction stir welding

Currently, the independently developed robot friction stir welding has obtained the EU CE certification and reached the internationally recognized standards. Risong robot friction stir welding is based on a high-precision and high-torque robot body, laying a solid foundation for high-strength and high-precision friction stir welding. With performance advantages such as 250Hz real-time pressure monitoring and adjustment, independent intellectual property rights, high rotation speed spindle, constant pressure static shoulder, etc., it ensures the stability of the welding process in real time, reaches the maximum welding speed of 7000rpm, torque of 76Nm, widens the welding process window, and achieves high-quality welding of all aluminum alloy, magnesium alloy, and other nonferrous metals without flash, polishing, and post processing.

Risong Weldstone has also developed a new generation of Nadel spindles with high power and constant torque, which have multiple degrees of freedom functions such as large swing angle, rotation, and fine adjustment, breaking through the accuracy control challenges of the thin-walled curved surface friction stir welding spindle system. On the basis of meeting the indicator of green manufacturing, it combines the advantages of robots and has the characteristics of high flexibility, high efficiency, and intelligence.

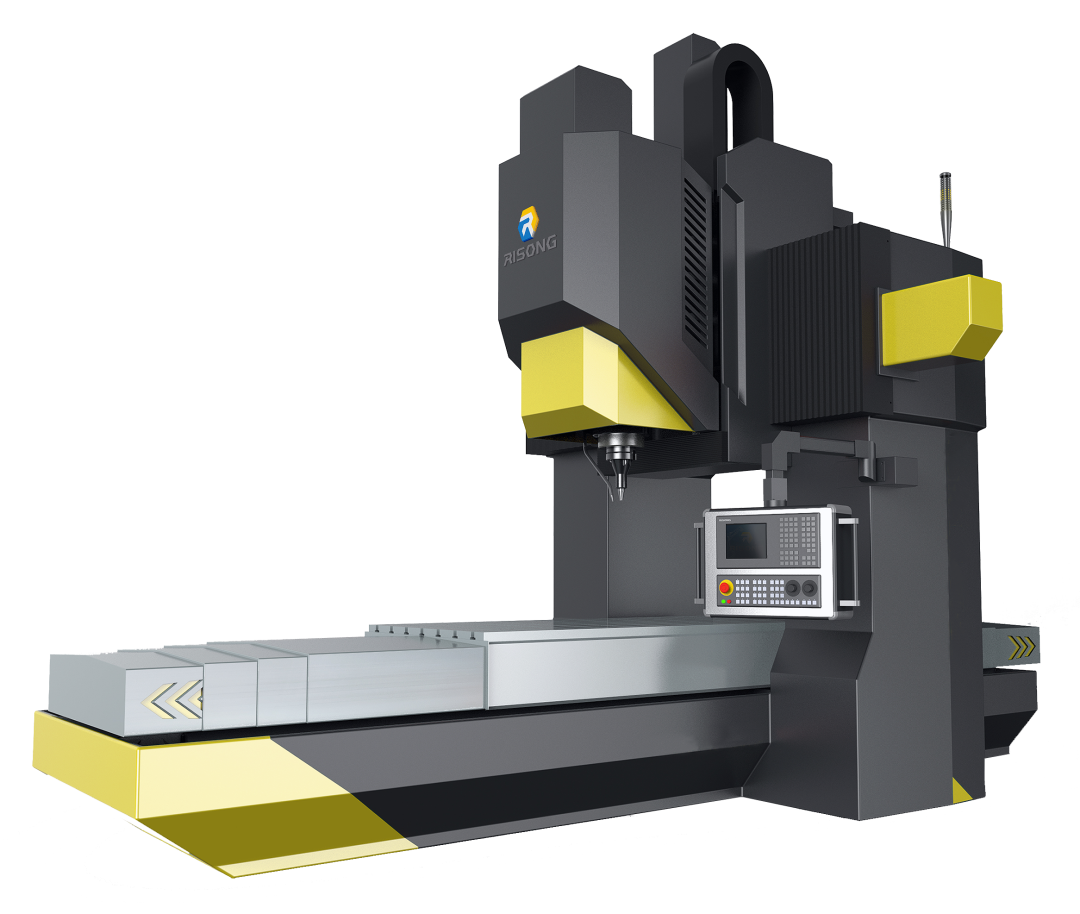

3 Gantry type friction stir welding

Gantry type friction stir welding equipment is a high-end welding equipment developed based on the concept of high-end CNC machine tools. At the beginning of design, the overall structure has been fully optimized by finite element mechanics and kinematics/dynamics matching, ensuring the rigidity and motion stability of the bed. The main body of the equipment adopts high-quality casting secondary tempering treatment, which ensures excellent accuracy retention of the equipment; The constant overhang head design enables the mixing head to maintain consistent accuracy in the Z direction space; The equipment is manufactured using machine tool industry standards, which allows the equipment to have excellent accuracy and excellent reliability. It is mainly used for friction stir welding of large format planar two-dimensional sealing structures such as new energy battery packs, large water cooled plates, etc.

In addition, for aluminum alloy large thickness and large format special friction stir welding, it can achieve automatic welding of large format 3D welds with a single thickness of 40mm, a maximum length of 20m, and a maximum width of 16m. The equipment can be equipped with dual beam gantry, dual differential spindle, heavy-duty A/C swing head, retractable friction stir welding spindle, high-precision large torque turntable, constant pressure control, milling and welding integrated tooling, adaptive positioning and clamping functions. Special friction stir welding for large aluminum alloy storage tanks can achieve φ 800mm- φ 5000mm horizontal circumferential seam, φ 800mm- φ Welding of 5000mm vertical longitudinal seam. It has functions such as multi axis drive, extraction spindle, lining drive, and digital compression of the outer ring.

At present, Risong friction stir welding high-end equipment and technology have been industrialized in the fields of new energy vehicles, aerospace, shipbuilding, rail transit, 5G communication, and other fields, meeting the production demand of various manufacturing industries for high-quality welding of aluminum and magnesium light alloy, complying with the development trend of intelligent manufacturing, playing a significant demonstration effect in industry applications, promoting industry technology upgrading.

In the future, Relying on the advantages of friction stir welding technology and the location advantage of a Sino German joint venture, Risong Weldstone will continue to make breakthroughs in applications in various industries around the world, effectively occupy emerging industrial markets, continue to develop, and seek a world benchmark for intelligent manufacturing of lightweight materials and industry development.